Aikin rarrabuwar kai ta atomatik na tayoyin da aka gama a cikin Shengshitailai Rubber ya fahimci ikon sarrafa kansa da ikon gano bayanai na sufuri, rarrabawa, palletizing, adanawa da isarwa, gami da inganta ingantaccen aiki da rage farashin aiki ga kamfanoni.

Domin daidaitawa ga ci gaban masana'antu da bukatar kasuwa, da kuma inganta samar da inganci da rage farashin aiki, a cikin 2015 Qingzhou Shengshi tailai Rubber Company (a nan bayan da ake kira "Sheng Tai") ya yanke shawarar samar da nau'i na 12 miliyan. na gama taya ta atomatik rarrabuwa, ta hanyar ci gaba da ingantawa da kuma aikin zanga-zanga tare da rabin shekara, karshe tabbatar da mafita ga cikakken bayarwa ga kammala taya ajiya da rarraba tsarin hadewa.

Shengshi Tailai Rubber

Tsarin rarrabuwa ta atomatik don tayoyin da aka gama

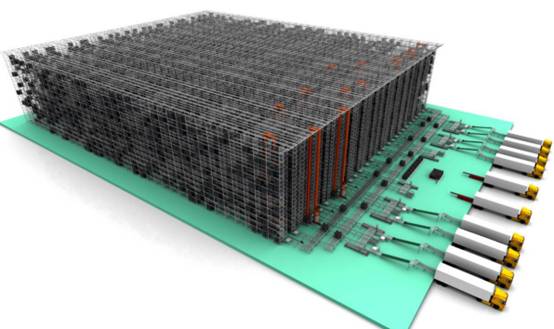

Aikin rarrabuwar kai ta atomatik ya ƙunshi yanki na murabba'in murabba'in 21000, jimillar jari kusan RMB miliyan 200, Shengtai mai sarrafa kansa ya ƙunshi aikin isar da kai ta atomatik, rarrabawa, tari ta atomatik, tsarin ajiya ta atomatik bayan ganowa. Karkashin fahimtar tsarin sarrafa bayanai na ERP, tsari mai hankali da rashin mutuntawa, fitowar tayoyin tayoyin miliyan 12 na shekara-shekara sun cika buƙatu da ci gaba na dogon lokaci na Shengtai.

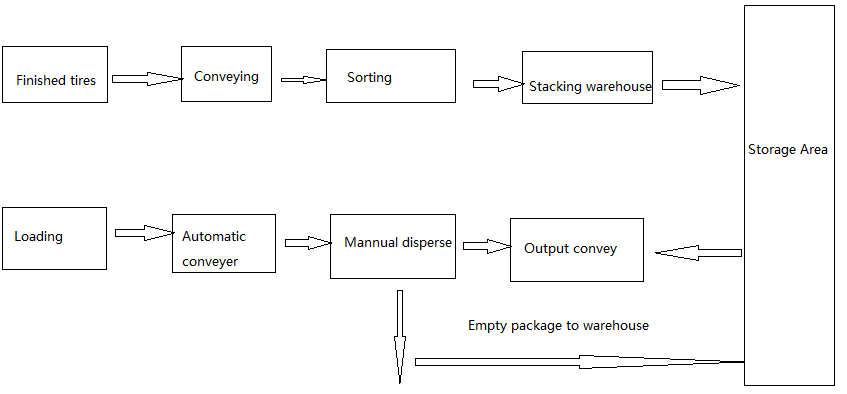

Tsarin yana amfani da tararrakin da aka haɗa don ajiya, jimlar ramuka 14, saiti 14 sama da mita 30 na stacker, mafi girman kaya na pallets 50400. Ana jigilar samfur ɗin zuwa wurin sito a bene na biyu, ta hanyar tsarin sikanin sikandire na samfuran da suka cancanta da samfuran da ba su cancanta ba don rarrabuwa ta atomatik, sannan robot ɗin palletizing ta atomatik zuwa ajiya ta hanyar layin watsawa da aka aika zuwa wurin ajiya ta nau'ikan 14 na injin stacker, a bene na farko. na taya da aka gama ta hanyar na'urar abin nadi na sarkar, mai ɗaukar bel na telescopic da sauran kayan aikin jigilar kaya don kammala bayarwa.

Taswirar tsari gabaɗaya

1. Ƙare kayayyakin ajiya a cikin sito

Na'urar gwaji mai jujjuyawa ce ta gwada ƙãre tayan taron bitar. Idan an wuce binciken, ana jigilar shi zuwa wurin rarrabawa a bene na biyu na gidan kantin a tsaye ta hanyar corridor. Tiresare maras kyau da aka kai wurin gyarawa. Tayoyin da suka cancanta bayan gyare-gyare suna sake komawa kan layi ta hanyar corridor zuwa wurin rarraba bene biyu.

Rarraba layi a cikin 2ndAna jerawa wurin rarrabuwar ƙasa bisa ƙayyadaddun ƙayyadaddun tashoshi 12 na rarrabawa, kuma robot ɗin Longmen yana ɗaukar tayoyin kai tsaye zuwa wurin da aka keɓe na tebur ɗin ajiyar wayar hannu. Lokacin da aka tara tayoyi guda ɗaya a kan wani dandali a kan dandali na ajiya na wayar hannu, robot ɗin Longmen yana ɗaukar dukkan tarin tayoyin zuwa wurin da aka keɓe a ɗakin karatu na Longmen. Dangane da umarnin bayanan WMS, mutum-mutumi na Longmen ya ɗauki tarin tayoyin da suka yi daidai da lambar tari a kan tire ɗin da babu kowa. Bayan tiren ajiyar kayan abinci na RGV da aka yi jigilarsu zuwa kwamfutar da aka kayyade, sarrafa kayan da aka keɓance.

A: rarrabuwa mara kyau: na'urar rarraba tana sanye take da wani abin da ba a saba gani ba, kuma an sanya tayar da ta ƙare a cikin tashar sarrafawa ta hanyar jagora sannan a adana shi a cikin sito.

B: a cikin tsarin ajiya na gano bayyanar da kuma sake duba lambar lambar, kamar yanayin rashin daidaituwa, sarrafa ta atomatik zuwa tashar sarrafawa mara kyau, sarrafa hannu, sa'an nan kuma warehousing.

2. Kaya da aka gama Ex- sito

Bayan WMS ta aika da umarnin jigilar kaya, tire ta atomatik tana sanya kaya zuwa na'ura mai ɗaukar kaya, sannan layin isar da jigilar kayayyaki ya aika zuwa tashar isar da kayayyaki daidai, ta hanyar farantin wucin gadi, lakabin, mai ɗaukar bel, taya mai tsaye, mai ɗaukar bel ɗin telescopic zuwa babbar motar don bayarwa.

Kayan aiki mara amfani: tireren taya da aka gama bayan an raba su daga pallet, ma'aikata za su aika da hannu zuwa ma'ajiyar atomatik

A cikin dukan tsarin kowane taya bayanai tracking, da ajiya da bayanai na iya zama a cikin cikakken atomatik management, don kauce wa wucin gadi kurakurai lalacewa ta hanyar ajiya da kuma bayarwa kurakurai, da tasiri aiwatar da bayanai traceability, ajiye mai yawa aiki halin kaka na Enterprises, da kuma inganta theo peration yadda ya dace.

Lokacin aikawa: Satumba-02-2022